What Is The Biomass Pyrolysis Process?

Biomass pyrolysis involves thermal decomposition involving biomass materials that occur when oxygen is absent. This is a chemical reaction that is fundamental and the precursor for combustion and gasification processes that occur within the first 2 seconds. The products created from biomass pyrolysis plant mainly include charcoal, wood vinegar, tar and gases that include carbon dioxide, carbon monoxide, hydrogen, and methane.

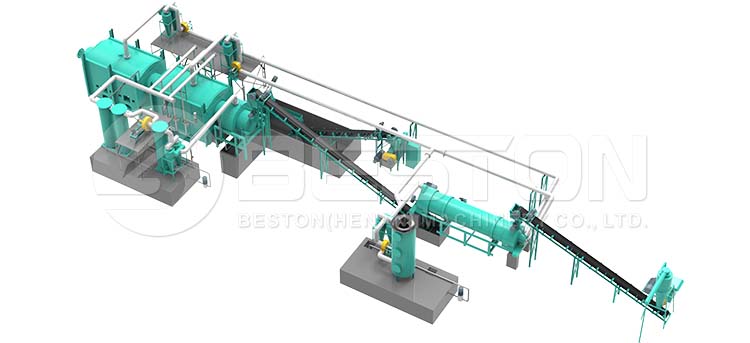

Biomass Pyrolysis Plant Design

Biomass pyrolysis processes include both successive and simultaneous reactions when organic materials are heated in non-reactive atmospheres. The thermal decomposition of an organic component in biomass begins at 350 °C–550 °C, which can go up to 700 °C–800 °C when oxygen or air is absent. The chains of oxygen, hydrogen, and carbon compounds present in biomass that start off long, will break-down into molecules that are much smaller into gases, solid charcoal, and vapors (oils and tars) under the conditions of pyrolysis. The extent and the rate of decomposition relating to each component will depend on process parameters associated with the pressure, biomass heating-rate, reactor temperature, feedstock, reactor configuration and more.

Depending on the temperature (final) and the actual thermal environment, pyrolysis yields primarily biochar at the lower temperatures, under 450 degrees Celcius, when heating rates are slow. Biomass pyrolysis will yield mainly gases when the temperature exceeds 800 degrees Celcius, with the faster heating rates. At intermediate temperatures, under a high heating rate, the main product produced is charcoal.

Charcoal Processing Plant in Ukraine

Fast And Slow Pyrolysis

Biomass pyrolysis processes are usually classified as either fast or slow. Pyrolysis that is slow often takes a number of hours, which mainly results in the production of biochar. Fast pyrolysis, on the other hand, yields 60% charcoal and can take a few seconds to reach complete pyrolysis. That’s why the biomass pyrolysis plant is also known as charcoal production plant. More details can be found: https://ecobeston.com/charcoal-making-machine/.

Benefits Of Biomass Pyrolysis Plant

Pyrolysis is often performed at locations that are remote and relatively small-scale which helps to increase the overall energy density associated with biomass resources and to lower handling and transport costs. It also offers a way to get rid of organic waste that would otherwise land up in landfills. Heat transfer happens to be one of the most important elements in pyrolysis, due to the fact that a pyrolysis process happens to be endothermic, which means enough heat transfer needs to be present to match up to the process heat requirements. Biomass pyrolysis provides an attractive and flexible method to convert organic materials into useful energy products, that are used successfully in the production processes of chemicals, power, and heat.

Today there are many different types of biomass feedstocks that are used for biomass pyrolysis processes, such as coconut shell, sawdust, wood (https://ecobeston.com/wood-pyrolysis-plant/), etc. Biomass pyrolysis processes are highly dependent on how much moisture the feedstock contains. This should ideally be around 10%. Waste streams that contain high levels of moisture require a drying process before they can undergo pyrolysis.

In addition, charcoal that is produced is useful on farms as a type of soil amender that is extremely absorbent which increases the ability of the soil to retain agricultural chemicals, nutrients, and water, which helps to prevent soil erosion and water contamination. Bio-char used in the form of a soil-amendment often offsets most of the issues linked with the removal of crop residues.