Marvels of Plastic Pyrolysis Plants: Turning Waste into Pyrolysis Oil

In a world grappling with the mounting challenges of plastic waste, plastic pyrolysis plants emerge as the unsung heroes of the sustainable technology landscape. These remarkable facilities, often tucked away in industrial zones, have the power to transform discarded plastics into valuable resources. Let’s embark on a journey to unravel the intricate realm of plastic pyrolysis plants and their pivotal role in mitigating the plastic waste crisis.

Grasping the Essence of Plastic Pyrolysis

Before delving into the world of plastic pyrolysis plant, it’s crucial to understand the heart of this technology: pyrolysis. Pyrolysis is a thermochemical process that involves the breakdown of organic materials, in this case, plastics, at elevated temperatures in the absence of oxygen. This process initiates the transformation of complex polymer structures into simpler compounds, a hallmark of pyrolysis.

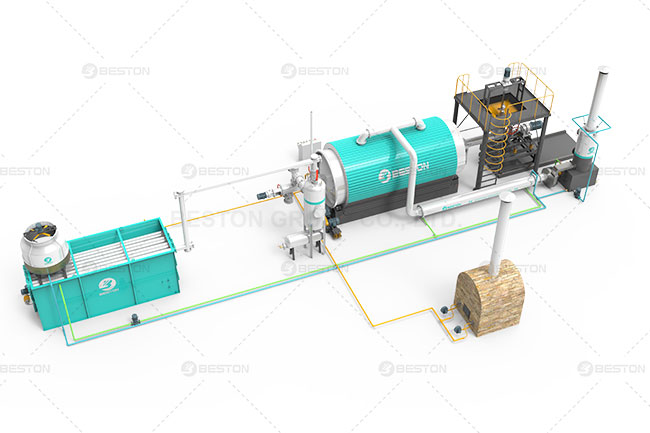

Pyrolysis Plant -To Process Plastic

Plastic Pyrolysis Plants: A Closer Examination

The Pyrolysis Process

At the core of these plants lies the intricate pyrolysis process. It commences with the feeding of plastic waste, which can include a wide array of materials, into a high-temperature chamber. Inside this controlled environment, plastics are subjected to intense heat, resulting in the breakdown of long polymer chains into smaller hydrocarbons. These transformed compounds can be further processed into valuable products.

Key Components

Feeding System: The journey begins here, as plastic waste is fed into the plant.

Pyrolysis Reactor: The heart of the operation, where plastics undergo thermal decomposition, releasing valuable hydrocarbon gases and leaving behind a carbon-rich residue.

Gas Cleaning System: The captured gases are cleaned and purified, ensuring that only environmentally friendly emissions are released.

Condensation System: This unit cools the gases, converting them into valuable liquid fuels, such as pyrolysis oil.

Solid Residue Collection System: The final product, carbon-rich char or coke, is carefully collected and can be used in various applications. Get pyrolysis machine cost.

Transforming Plastic Waste into Valuable Resources

Plastic pyrolysis plants have a remarkable ability to convert plastic waste, which often ends up in landfills or pollutes the environment, into valuable resources. This transformative process results in several high-demand products:

1. Pyrolysis Oil

This liquid product, derived from the condensation of pyrolysis gases, has applications in various industries. It can be used as a fuel for industrial processes or even as a precursor for the production of gasoline and diesel.

2. Carbon Black

Carbon black, a fine powder, is a valuable material used in the production of tires, plastics, and inks. It’s a sought-after resource in industrial applications.

3. Synthetic Gas (Syngas)

Syngas, a mixture of hydrogen and carbon monoxide, can serve as a clean and versatile source of energy or as a feedstock for the chemical industry.

4. Solid Residues

The carbon-rich solid residues, known as char or coke, find applications in metallurgy and as a soil conditioner in agriculture.

BLJ-6 BLJ-10 Plastic Pyrolysis Machine

The Economic Dynamics of Plastic Pyrolysis Plants

Understanding the financial aspects of plastic pyrolysis plant for sale is pivotal for investors and entrepreneurs venturing into this eco-conscious domain. Several factors influence the economic landscape:

1. Plant Capacity

The size and capacity of the plant significantly impact the initial investment. Larger facilities can process more plastic waste but require a higher upfront cost.

2. Plastic Feedstock

The type and source of plastic feedstock play a vital role in both cost and efficiency. Locally sourced plastics or specific plastic categories may be more cost-effective.

3. Operational Expenses

Maintenance, labor, and energy consumption are essential considerations in the ongoing operational expenses of plastic pyrolysis.

The Green Advantages of Plastic Pyrolysis Plants

The allure of plastic pyrolysis plants extends beyond their economic viability. These facilities offer a range of environmental benefits:

Waste Diversion: They help reduce the burden on landfills and curb plastic pollution.

Resource Recovery: Through pyrolysis, plastic waste is transformed into valuable resources, contributing to a circular economy.

Energy Generation: The captured gases can be used as a clean energy source, reducing the reliance on fossil fuels.

Emissions Reduction: Advanced gas cleaning systems ensure that emissions are environmentally friendly and compliant with regulations.

Paving the Way for a Sustainable Future

In an era marked by heightened environmental consciousness and the pressing need to address plastic waste challenges, plastic pyrolysis plants offer a beacon of hope. These facilities have the potential to reduce plastic pollution, recover valuable resources, and provide sustainable energy solutions. They represent an essential part of the path toward a greener and more sustainable future, where waste is transformed into wealth, and environmental conservation is paramount. More related information on Beston Group.