The Transformative Role of Biomass Pyrolysis Technology in Sustainable Agriculture

In the intricate tapestry of sustainable agriculture, an innovative force emerges – biomass pyrolysis technology. This groundbreaking method not only addresses waste management challenges but also offers a transformative pathway towards enriching soil health and fostering sustainable farming practices.

Unveiling the Essence of Biomass Pyrolysis Technology

The Crucial Role of Biomass

Biomass, an organic matter derived from plants and animals, becomes a cornerstone in the journey towards sustainable agriculture. The utilization of residual biomass from agricultural activities, forestry, or organic waste marks the inception of biomass pyrolysis technology.

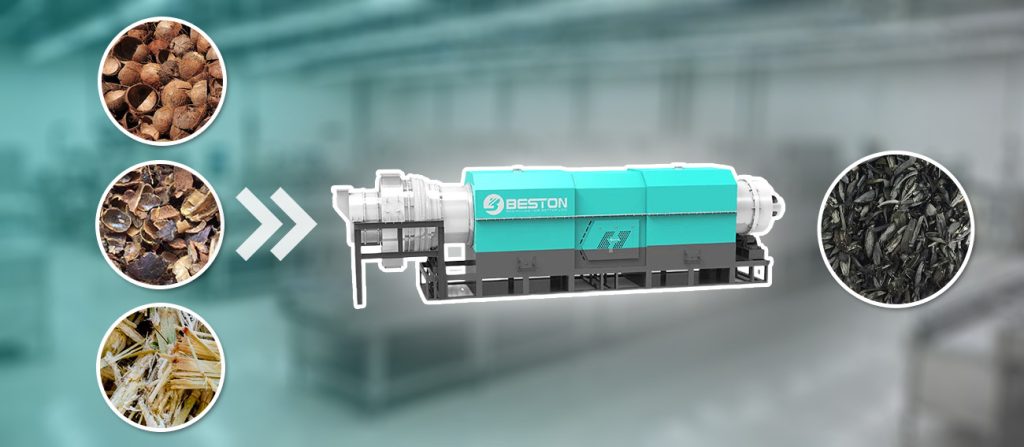

Diverse Feedstock Potential

The beauty of biomass pyrolysis technology lies in its adaptability to a diverse range of feedstocks. Agricultural residues, woody biomass, or even dedicated energy crops can undergo pyrolysis, unlocking their latent energy and nutrient potential for agricultural applications.

The Pyrolysis Process Unveiled

At the heart of biomass pyrolysis technology is the pyrolysis process in charcoal machine, a thermochemical conversion method that involves subjecting biomass to high temperatures in the absence of oxygen. This controlled environment induces the breakdown of complex organic compounds within the biomass, leading to the creation of valuable byproducts.

Three Stages of Pyrolysis

The pyrolysis process within a biomass pyrolysis plant unfolds in three stages: drying, pyrolysis, and char activation. In the drying stage, moisture is removed, paving the way for the pyrolysis phase, where the actual thermal decomposition occurs. The final stage involves activating the resulting char, enhancing its efficacy for soil application.

The Symbiosis with Sustainable Agriculture

Soil Enrichment Through Biochar

A key byproduct of biomass pyrolysis technology is biochar – a carbon-rich, porous material with remarkable soil-enhancing properties. The incorporation of biochar into soil improves water retention, nutrient availability, and microbial activity. This synergy lays the foundation for sustainable and resilient agricultural ecosystems.

Carbon Sequestration Benefits

Beyond soil enhancement, biochar plays a pivotal role in carbon sequestration. The carbon captured during the pyrolysis process is effectively sequestered in the biochar, mitigating greenhouse gas emissions and contributing to climate change mitigation efforts.

Nutrient-Rich Syngas for Agriculture

In addition to biochar, biomass pyrolysis technology generates syngas – a synthesis gas comprising hydrogen, carbon monoxide, and methane. This nutrient-rich syngas, when utilized as a soil amendment, provides a supplementary source of carbon and energy for soil microbes. This fosters a dynamic microbial community, crucial for nutrient cycling and overall soil health.

Unraveling the Technical Nuances

The Design and Engineering of Biomass Pyrolysis Plants

The biomass pyrolysis plant is meticulously engineered to optimize the pyrolysis process. The design considerations encompass reactor types, heat transfer mechanisms, and process control systems. A variety of reactor configurations, such as fluidized bed reactors or rotary kilns, can be employed based on the specific feedstock and desired outcomes.

Process Control Systems

The efficiency of a biomass pyrolysis plant hinges on advanced process control systems. Automated temperature regulation, real-time monitoring, and feedback mechanisms ensure that the pyrolysis conditions are precisely controlled, maximizing the yield of valuable byproducts.

Tailoring Biochar Properties Through Pyrolysis Conditions

The properties of biochar, a linchpin in biomass pyrolysis technology, can be tailored by adjusting pyrolysis conditions. Variables such as temperature, heating rate, and residence time influence the physical and chemical characteristics of biochar. This customization allows farmers to adapt biochar applications to the specific needs of their soils.

Economic Viability and Return on Investment

Initial Investment Considerations

Embarking on the adoption of biomass pyrolysis technology involves an initial investment in the installation of biochar pyrolysis equipment. Factors influencing the investment include plant capacity, feedstock availability, and technological specifications. While the upfront costs may seem substantial, the long-term benefits and economic viability often outweigh these initial expenditures.

Byproduct Commercialization

The revenue potential of biomass pyrolysis technology extends beyond soil enrichment. Byproducts like biochar and syngas can be commercialized, contributing to the overall return on investment. The growing market demand for sustainable agricultural inputs positions biochar as a valuable commodity in the agricultural and horticultural sectors.

Environmental Sustainability and Climate Resilience

Mitigating Greenhouse Gas Emissions

The adoption of biomass pyrolysis technology aligns with global efforts to mitigate greenhouse gas emissions. By sequestering carbon in biochar and capturing syngas for energy applications, the technology offers a tangible solution for reducing the carbon footprint associated with conventional agricultural practices.

Climate-Resilient Agriculture

Sustainable agriculture necessitates resilience in the face of climate change. Biomass pyrolysis technology contributes to climate-resilient agriculture by enhancing soil water retention, minimizing nutrient leaching, and promoting microbial diversity. These factors collectively bolster the ability of agricultural ecosystems to withstand climate-induced challenges.

Challenges and Future Innovations

Addressing Residuals and Contaminants

Challenges persist in addressing residual contaminants and ensuring the complete removal of impurities during the pyrolysis process. Ongoing research focuses on refining pyrolysis conditions, exploring innovative sorbents, and developing post-treatment technologies to enhance the purity of biochar. Turn to Beston Group for sustainable biomass recycling solutions.

Technological Advancements

The landscape of biomass pyrolysis technology is characterized by continuous technological advancements. From sensor-based monitoring systems to novel reactor designs, ongoing innovations aim to improve efficiency, reduce energy consumption, and enhance the overall sustainability of the pyrolysis process.

Conclusion: A Sustainable Harvest Through Biomass Pyrolysis

In conclusion, the contribution of biomass pyrolysis technology to sustainable agriculture represents a harmonious blend of technological innovation and environmental stewardship. The transformative potential of biochar and syngas extends far beyond waste management, offering a regenerative approach to soil health and climate resilience in agriculture.

As the agricultural landscape evolves, the adoption of biomass pyrolysis technology stands as a testament to the possibilities that arise when science and nature collaborate. This dynamic synergy not only enriches the soil but also lays the groundwork for a sustainable and bountiful future in agriculture.