Economic Insights: Understanding the Total Cost of Plastic Pyrolysis Recycling

Plastic pyrolysis involving the thermal decomposition of plastic waste into valuable products, presenting an environmentally conscious alternative to traditional disposal methods. However, for businesses and organizations contemplating the adoption of plastic pyrolysis, a crucial aspect looms large: the plastic pyrolysis project cost.

Decoding the Components of Plastic Pyrolysis Project Cost

1. Capital Investment

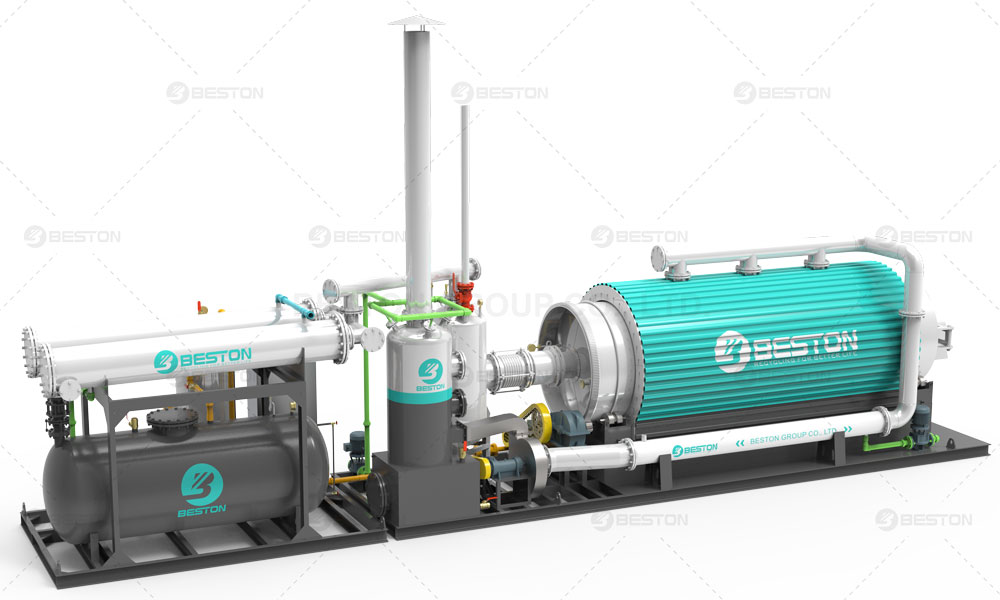

Launching a plastic pyrolysis plant project venture necessitates a significant upfront investment. The acquisition of state-of-the-art pyrolysis reactors, distillation columns, and ancillary equipment forms the backbone of the capital expenses. These sophisticated apparatuses are engineered to withstand the harsh conditions required for efficient plastic breakdown.

2. Feedstock Acquisition

The success of a plastic pyrolysis project hinges on the quality and quantity of the feedstock. The term “feedstock” refers to the raw plastic material designated for pyrolysis. Acquiring a consistent and reliable supply of diverse plastic waste streams demands strategic partnerships and logistics, thus influencing the overall project expenditure.

3. Operational Costs

Once the plastic to oil machine is operational, a web of operational costs ensues. This includes expenses associated with energy consumption, labor, maintenance, and waste management. Skilled personnel are indispensable for overseeing the intricate processes involved in plastic pyrolysis, contributing to the operational outlay.

4. Regulatory Compliance

Navigating the regulatory landscape is an imperative facet of any environmentally driven project. Compliance with environmental standards, safety protocols, and waste disposal regulations adds another layer to the plastic pyrolysis project cost. This ensures that the venture aligns with legal frameworks and fosters responsible environmental stewardship.

5. Technology Upgradation

In the dynamic realm of waste management technologies, continuous improvement is paramount. Allocating funds for ongoing research and development, coupled with periodic technology upgrades, safeguards the efficiency and competitiveness of the plastic pyrolysis plant. This proactive approach is essential for staying ahead in a rapidly evolving industry.

Unraveling the Nuances of Plastic Pyrolysis Project Cost

The total cost of a plastic pyrolysis recycling solution extends beyond the mere sum of its parts. It embodies a holistic approach, intertwining technological prowess with environmental responsibility. Let’s delve deeper into the intricacies of these cost components.

1. Capital Investment: Setting the Foundation

The first cornerstone of the plastic pyrolysis project cost is the capital investment required for procuring cutting-edge pyrolysis plant. Pyrolysis reactors, the linchpin of the process, are engineered to withstand extreme temperatures, ensuring optimal plastic decomposition. The distillation columns, responsible for separating the pyrolysis products, further contribute to the initial capital outlay.

This substantial investment, though daunting, is a testament to the long-term vision of a sustainable future. The technology’s potential to transform plastic waste into valuable resources, such as bio-oil and syngas, justifies the upfront financial commitment.

2. Feedstock Acquisition: Securing the Raw Material

The quality and availability of feedstock play a pivotal role in determining the efficiency of a plastic pyrolysis plant. Investing in a robust network for procuring diverse plastic waste streams ensures a continuous supply, minimizing downtime and maximizing operational efficiency.

While the plastic pyrolysis project cost associated with feedstock acquisition might vary based on geographic location and local waste management dynamics, it remains a fundamental component. Strategic partnerships with waste collection agencies and a proactive approach to securing feedstock contribute to the overall success of the venture.

3. Operational Costs: Sustaining Efficiency

With the plant in full swing, operational costs come into focus. Energy consumption, a critical element in the pyrolysis process, necessitates a judicious approach. The employment of skilled personnel, trained in the nuances of pyrolysis operations, adds to the ongoing expenses but ensures the seamless execution of the recycling process.

Maintenance costs, often overlooked in initial assessments, become increasingly relevant as the plant ages. Regular inspections, repairs, and upgrades are vital for preventing downtime and maintaining the plant’s productivity. Balancing these operational costs is imperative for achieving both environmental and economic sustainability.

4. Regulatory Compliance: Upholding Environmental Integrity

Adhering to environmental regulations is not just a legal obligation but an integral part of the plastic to fuel plant project cost. This involves investing in robust safety measures, waste disposal protocols, and emissions control systems. While these measures contribute to the financial outlay, they are indispensable for fostering a responsible and ethically sound operation.

The cost of regulatory compliance extends beyond monetary considerations; it underscores the commitment to environmental preservation. Striking a balance between compliance and operational efficiency is a delicate but necessary aspect of the venture.

5. Technology Upgradation: Staying Ahead in the Innovation Curve

In the dynamic landscape of waste management, technology evolves rapidly. Allocating resources for continuous research and development, coupled with periodic technology upgrades, positions the plastic pyrolysis plant on the forefront of innovation. This proactive investment ensures the longevity and competitiveness of the venture.

The plastic pyrolysis project cost associated with technology upgradation is an investment in the plant’s resilience and adaptability. Embracing advancements in pyrolysis technology not only enhances efficiency but also opens avenues for processing new types of plastic waste, broadening the plant’s scope and impact.