Workings Of Modern Municipal Solid Waste Sorting Machine

There are places located all over the planet where disposing of increasing quantities of garbage is becoming a major problem. Many landfill sites are currently overflowing with waste materials that could be recycled. Fortunately, people everywhere are becoming more aware of the environmental damage mounting trash is causing, so much so that it is now possible to run a profitable garbage recycling machine with a municipal solid waste sorting machine. Many governments in European countries even offer recycling facility owners state grants and tax subsidies for their contributions to helping to manage waste disposal problems.

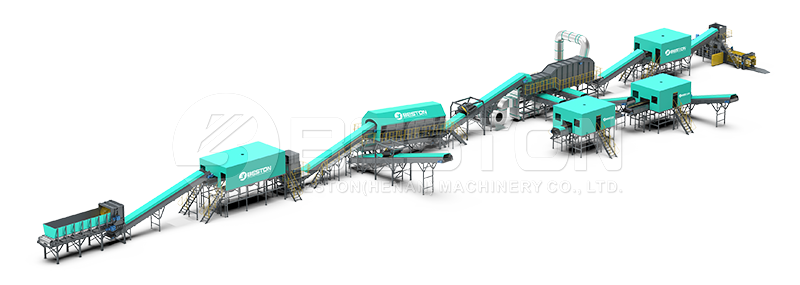

Waste Sorting Plant Design

The truth is that there have been major advances in engineering technology in recent decades, and today’s municipal solid waste sorting machines are more effective than ever at sorting mixed solid garbage into categories of recyclable materials. A typically MSW sorting plant is compromised of multiple individual complex modules that can also work in unison to automatically separate, process and package up all manner of city trash.

Sorted Waste Material Groups

When mixed garbage first arrives at a municipal solid waste processing plant, it is manually or automatically located onto a conveyor belt system and transported through air sorters. Next, the mixed trash passes over a magnetic separator, which removes items containing metals like steel and iron. As the mixed debris continues its passage through an MSW sorting plant, it is separated into multiple recyclable material groups including glass, rubber, plastic, masonry, organic matter, combustibles, metals and more. All of the items in the mixed trash that are not recyclable gather at the end of the conveyor belt system where they are collected and packed ready for disposal.

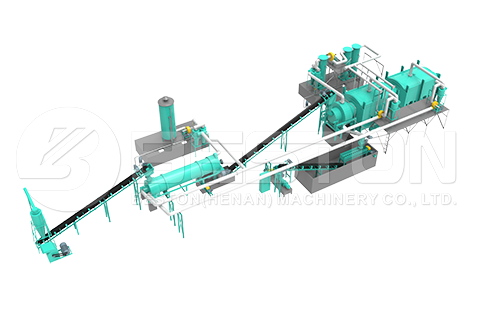

Once the city trash has been sorted into separate material groups, each material group progresses through the recycling facility for further processing into valuable commodities. The plastic and rubber materials are typically sent to a pyrolysis machine where they are converted into carbon black, combustible gas and fuel oil. The pyrolysis fuel oil is often sent for further refinement and turned into diesel oil and gasoline.

The organic matter material group is typically formulated into rich fertilizer and sold to the agriculture industry. Sometimes plant operators might decide to convert the organic matter to biogas instead of fertilizer using a fermentation system.

All combustible waste materials, such as fibers, textile fabric, wood, cardboard, etc., are put through further carbonization. The masonry materials, such as sand, stones, dust, etc., are converted into construction bricks.

Carbonization Machine Design

No Pollution

One of the best things about modern municipal solid waste sorting plants is that they do not produce any pollution during operation. Atomization systems, odor removers, and advanced smoke filters ensure the working environment inside a plant are safe for workers.

There are lots of MSW sorting machines for sale online. In order to avail of the best prices on garbage separation equipment, you need to be ready to check out overseas suppliers. You will find that many manufacturers of garbage treatment plant based in Asia offer unbeatable prices on different plant models. Just make sure you study each machine’s specifications carefully.