Various Types Of Beston Tyre Pyrolysis Plant For Sale

If you are thinking about starting an eco-friendly scrap tire recycling business, you are probably looking for an affordable tyre pyrolysis plant for sale. On the internet, you will find many of such plants for sale all with different sets of benefits and drawbacks. You will need to decide which areas you are prepared to compromise on in order to stay within your budget. You also want to ensure you buy a tyre pyrolysis plant for sale big enough to keep up with the daily processing demands of your business.

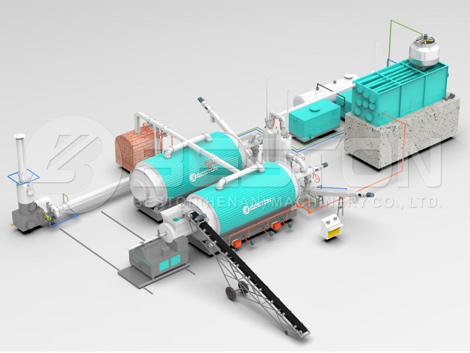

Scrap Tyre Pyrolysis Plant

Beston has a wide range of tyre pyrolysis plants for sale including the BLJ-6, BLJ-10, BLJ-16, and BLJ-20. This post will discuss some of the main specifications of different models to help you choose the best plant for your tyre recycling business. To begin with, let’s consider the BLJ-6 and BLJ-10, which are both batch plants. The reactor in a plant with a batch working method has to be cooled down to collect end products after every cycle. Beston’s entry-level batch plant, the BLJ-6 has a daily capacity of 6T and uses 24kwh/h. The BLJ-10 model has a slightly higher daily processing capacity of between 8T and 10T. It uses 30kw/h. Click here to know more: https://bestonpyrolysisplant.com/.

The reactors in all of Beston’s plants are expected to last between 5 and 8 years. They can be fuelled by wood, natural gas, charcoal, LPG, etc. Water cooling condensers are used to turn vapor into pyrolysis oil. The resulting pyrolysis oil can also be further refined in a distillation machine. Further end products from tire pyrolysis include steel wire, carbon black, and combustible gas. All of these end products are sought-after in the global marketplace, so tire recycling businesses should not have difficulty finding buyers for all the pyrolysis oil, carbon black, combustible gas, and steel wire they produce each day. Get tyre pyrolysis machine cost here.

BLJ-10 Pyrolysis Plant Shipped to Canada

While there are many other manufacturers with tyre pyrolysis plants for sale, Beston is many customers’ preferred choice. Some of the things that make the brand’s plants stand out are great energy efficiency, low emissions, innovative feeding and discharge systems, and excellent after-sales services. The brand’s plants are also 100% explosion-proof and constructed from fire-proof high-quality materials.

Beston has decades of experience exporting tyre pyrolysis plants to customers around the world. Their engineers are prepared to travel overseas to help customers with plant assembly, commissioning, and maintenance. Some of the countries they have exported reactors to include the UK, Turkey, Brazil, Indonesia, Australia, and South Africa. Why not visit the site: https://bestonpyrolysisplant.com/waste-tyre-recycling-plant/.