Things You Need To Know About The Cost Of A Pyrolysis Plant

If you are thinking of setting up your own pyrolysis plant and are thinking about the cost of a new pyrolysis plant, you have come to the right place. In today’s article, we will discuss the factors that affect the cost of pyrolysis plant. However, one thing is clear, a pyrolysis plant does not come cheap.

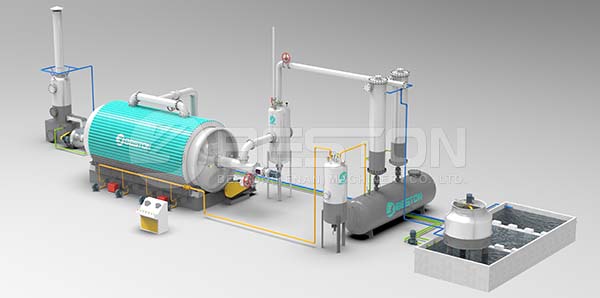

Beston Pyrolysis Plant

There is no standard answer to the question of the cost of a pyrolysis plant. Several factors such as the capacity of the plant, cost of land in your location, cost of fuel, cost of water and cost of labor as well as many other factors affect the overall cost of a pyrolysis plant. Another important thing you need to understand is that not all pyrolysis plants are created equal. Plants made from higher quality materials and longer service life with a higher level of automation are going to cost much more as compared to a plant with manual operation and decent quality materials.

Let’s begin with the level of automation. A continuous pyrolysis plant consists of several systems and naturally, it costs a lot more as compared to manual plants. However, the initial high cost of a fully automated plant is usually recovered within a few years due to higher efficiency and accuracy. Complete automation also results in fewer labor requirements which means you will save a lot of money in operational costs.

BLL-20 Continuous Pyrolysis Plant

Another important factor is the quality of materials used for making the plant. In a pyrolysis plant, the reaction chamber or the pyrolysis chamber needs to withstand extreme temperatures and pressure. If the chamber isn’t made of high-quality materials, it will need constant repairs which will not only add to the operational cost but will also lead to downtime. Therefore, it is better to invest in a high-quality pyrolysis plant as it has a longer service life.

The pyrolysis plant design also plays an important role in the operational expenses. Plants that are more energy-efficient and are capable of using a wide variety of fuels are going to be expensive as compared to plants lacking these features but the difference in the cost can be earned back within a few years. Please get more details here: https://bestonasia.com/pyrolysis-plant/.

Another factor that has a huge impact on the overall cost is the operational capacity of the plant. Higher capacity plants are naturally going to cost more but you will also be able to process a lot more raw material. It is recommended to choose a plant with optimum capacity as running a plant at less than optimal capacity will keep your operational costs high and might give an edge to your competitors.

Many buyers do not realize that a pyrolysis plant business is essentially a technology business. The technology used in the plant has a huge impact on the operational costs which means it has a huge impact on the profitability of your business.

To conclude, a pyrolysis plant made by Beston in China is more cost-effective and the price mainly depends on the factors mentioned above and several others. The most important thing you need to focus on is the quality of the materials used for making the plant, the reputation of the manufacturer in this industry, and after-sales service offered by the manufacturer. So, research several manufacturers and make sure they have excellent reputation and provide after sales service to set up a strong foundation for a consistently profitable pyrolysis plant.