Factors that Affect the Cost of Egg Tray Machines

An egg tray making machine, as the name implies, is primarily used to make trays and cartons used to transport eggs and fruits. The machinery uses readily available raw materials such as old newspapers, magazines, books, etc. It comes in a wide array of sizes and designs to meet all your needs and demands. However, with the many options available, picking the right one isn’t always easy. You need to be conversant with various aspects to ensure you pick a machine that will make your business more lucrative. Cost is a vital aspect and in this read, we’re going to focus on things that affect the price of an egg tray making machine(máquina para hacer cartones de huevo).

The Components

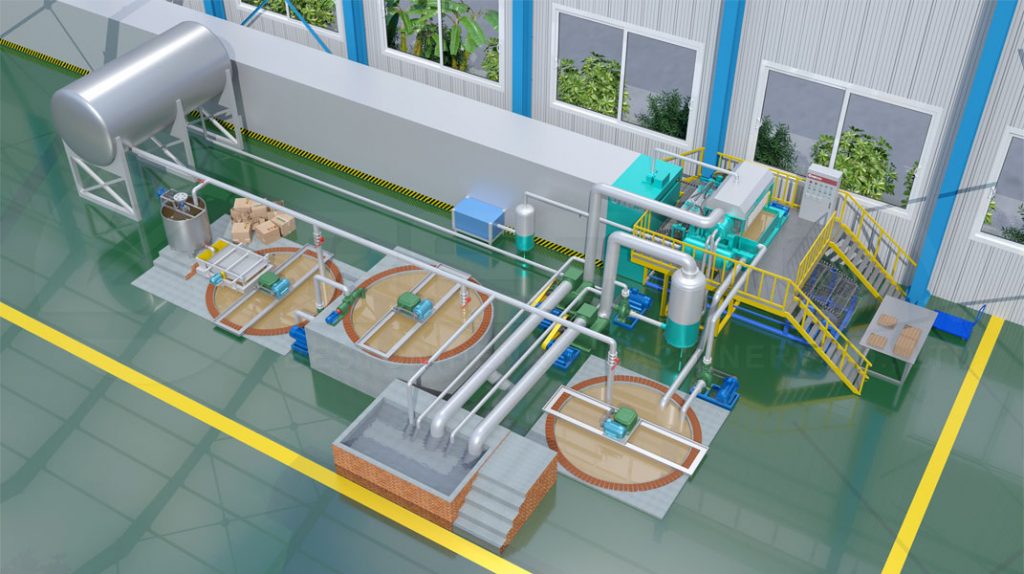

There are numerous components in an egg tray making machine. Examples include the pump, molds, pulper, packing system, drying system, refiner, etc. Pulp molding machines that use top-of-the-line components tend to go for a higher price, but they are less prone to malfunctions and last for longer.

Máquina para Hacer Bandejas del Huevo

Energy Efficiency

The raw materials required to run the machinery are not hard to get. Also, the best machinery, particularly automatic egg carton making machines(máquina para fabricar cubetas de huevos) require very few employees and this translates to lower labor costs. The largest expense in your egg carton and tray making business will be the fuel costs. This means that for the most savings, you need machinery with exceptional energy-efficiency ratings. This might cost you more upfront, but it will pay for itself in the long haul. The best equipment in this industry uses the latest technology to ascertain the lowest possible running costs. Most egg tray making machines can support an array of fuels such as diesel, natural gas, diesel, and even electricity.

The Maintenance Costs

The machinery maintenance costs are bound to cut into your yearly profits. As such, you will want to look for an egg carton making machine with a high stability rating. Also, it’s advisable to go for machinery(https://www.bestoneco.com/btf4-4-maquina-para-fabricar-cubetas-de-huevos-en-iraq/) that has easy to source spare parts. This way, if something happens, you will not have to deal with extensive downtime as you wait for the repairs to be done. The best manufacturers or suppliers in the industry provide repair and maintenance services after purchase.

The Manufacturers

It goes without saying that where you buy your machinery will have a substantial effect on the price. Manufacturers() that are well-known and have been in the industry for years are bound to sell their products at a higher price compared to the lesser-known ones. When shopping for an egg tray making machine(Diseños de plantas de BESTON), it is important to have your needs and budget in mind. Search for 3 to 5 manufacturers and compare their products, both in regard to features and cost. You want the best deal, not necessarily the most expensive or the cheapest. Do your homework and search for reviews and testimonials to ensure you are buying from a reputable seller.

And there you have it, the primary factors that affect the cost of an egg carton making machine. With these in mind, you should be in a position to make an informed decision.