When buying construction equipment, every aspect of a purchase must be scrutinized. This is especially true when it comes to front loading machinery. There are two types of equipment that can do the job well: the skid steer loader and a compact wheel loader. But which one is the best buy?

For many people, affordability is the deciding factor. On the surface, a skid steer loader may look more cost efficient than a wheel loader. Wheel loaders have expensive parts, which they can cost companies more when they are used.

Compact wheel loaders also have a greater upfront purchase price. The cost of undercarriage components makes wheel loaders significantly more expensive than their competition. The combination of these two things can make wheel loaders seem far less appealing to purchases.

However, these things are only one small piece of the puzzle. A compact loader offers a number of benefits that can justify its cost, and can even wind up saving businesses money.

One of the biggest advantages of a compact loader is that in can increase productivity. They’re easier to operate and have a greater bucket capacity, which means they can move much more material. You’ll be able to get much more work done with a bucket wheel loader.

Skid steer loaders will also need their tires replaced more frequently. Because of the way they operate, their tires will be subject to a lot of wear and tear. Tires are a big expense, and that cost can really add up over time.

Skid steer loaders will also need their tires replaced more frequently. Because of the way they operate, their tires will be subject to a lot of wear and tear. Tires are a big expense, and that cost can really add up over time.

That said, solid wheel loader tires tend to be significantly more expensive. In fact, they’re the single most expensive replacement item. The savings may not wind up being as significant as they might seem on the surface.

Compact wheel loaders do offer another very impressive advantage — their durability. These are heavy pieces of equipment, and they’re really built to last. If users take the time to care for their equipment properly, they can keep using a machine for front-line work for 10 years. Beyond that, they can still use it for the occasional job.

Their durability also means that they’re far less likely to become damaged. Accidents are going to happen, no matter how much you do to prevent them. It’s good to have equipment that can survive those minor mishaps without problems. The weight of the compact loader means it can survive almost anything.

Compact loaders also allow users to work in less than ideal conditions. A skid steer loader is virtually unusable on muddy or snowy terrain, but a compact loader can be used in all kinds of conditions. Snow shovel wheel loader is a good example. It’s worth paying more for a piece of machinery you’ll always be able to rely on.

As you can see, there are all kinds of advantages offered by compact wheel loaders. They’re an excellent piece of equipment that offers all kinds of value. They may seem expensive on the surface, but they can save users money in a number of ways.

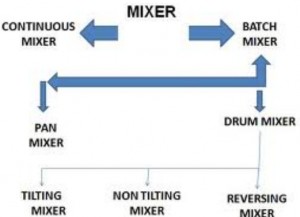

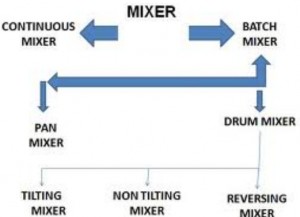

Concrete mixer is a machine that can mix sand, stones, aggregates and water etc. raw materials into concrete mixture. There are numerous types of concrete mixers in the market. We can classify them in the following methods.

Concrete mixer is a machine that can mix sand, stones, aggregates and water etc. raw materials into concrete mixture. There are numerous types of concrete mixers in the market. We can classify them in the following methods.

First, according to the power source of concrete mixers, they can be divided into diesel powered concrete mixer and electric powered concrete mixer. Diesel concrete mixer is especially suitable for those regions lacking of electricity.

Second, according to the movability of concrete mixers, we can classify them into fixed concrete mixers and portable concrete mixers. As the name suggests, fixed concrete mixer is fixed on a basis and its stationary, it has high efficiency and can be adopted in concrete batch plant, so it is widely applied to large size construction projects that need a long term to accomplish. On the contrary, portable concrete mixer is easy to move, they are widely used in small size construction site that need a short term to finish.

Third, according to the mixing principle of concrete mixers, they can be classified into self falling concrete mixer and forced concrete mixer. Self falling concrete mixer takes advantage of the raw materials’ weight during the mixing process. Self falling concrete mixers often are drum concrete mixers with small size, and they can be used to mix plastic concrete and semi-plastic concrete. Forced concrete mixer adopts forced mixing and its mixing effect is very strong, it has good mixing effect and high efficiency. Usually, it is adopted in a concrete batch plant. Forced concrete mixer is suitable for mixing hard dry concrete.

Forth, according to the operation mode of concrete mixers, they can be divided into continuous concrete mixer and circulating concrete mixer. Materials supply, mixing process and concrete discharge are conducted continuously in a long drum of continuous concrete mixer. The materials ratio and mixing time of continuous concrete mixer are hard to control and its mixing effect is not very good, so continuous concrete mixer is seldom used in modern construction. As for circulating concrete mixer, materials supply, mixing process and product discharge are separated with certain time interval. It has accurate weighing and good mixing effect. Therefore, most concrete mixers adopt circulating operation mode.

Forth, according to the operation mode of concrete mixers, they can be divided into continuous concrete mixer and circulating concrete mixer. Materials supply, mixing process and concrete discharge are conducted continuously in a long drum of continuous concrete mixer. The materials ratio and mixing time of continuous concrete mixer are hard to control and its mixing effect is not very good, so continuous concrete mixer is seldom used in modern construction. As for circulating concrete mixer, materials supply, mixing process and product discharge are separated with certain time interval. It has accurate weighing and good mixing effect. Therefore, most concrete mixers adopt circulating operation mode.

Fifth, according to the discharge mode of concrete mixers, they are divided into tilting type concrete mixer and non-tilting type concrete mixer.

Sixth, according to the shapes of concrete mixer drums, we can divide them into drum concrete mixer, double-conic concrete mixer, vertical shaft concrete mixer and horizontal shaft concrete mixer.

If you also want to see the real products of all kinds of concrete mixers, go to http://concretemachinerypro.com/concrete-mixer/. The supplier is a trust manufacturer of concrete plants and mixers with over 30 years experience. Buying from them can’t be wrong.