The Importance Of A Continuous Waste Tyre Pyrolysis Plant Business Plan

Are you searching for information regarding the cost of a continuous waste tyre pyrolysis plant? The truth is that there are a wide variety of different models of rubber pyrolysis machines for sale, each with different features, benefits, and drawbacks. This means that research about continuous pyrolysis plant is more important than ever.

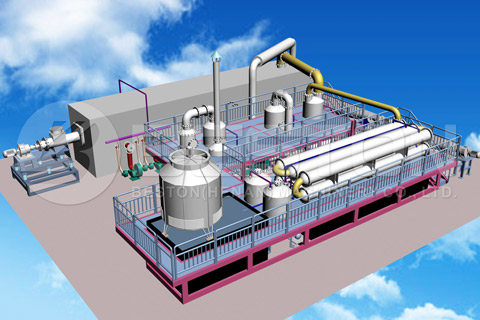

Shipment of Continuous Waste Tyre Pyrolysis Plant

Modern tire to oil machines, for example, are equipped with advanced features designed to make them more energy-efficient and cheaper to run. Such machines also adhere to stricter emissions standards, so they are more environmentally friendly than older tire recycling plant models. They achieve better eco-friendly ratings as they have better filters, which ensure zero air pollution during operation. Many people don’t realize how much filter technology has progressed over the course of the past decade.

It should be clear that if you are thinking about investing tire pyrolysis machine, your business plan needs to be designed around the cost of your largest investment, which will be the waste tire pyrolysis reactor. However, you also need to take into account other costs associated with setting up and running a profitable scrap tire processing business.

Buy Top Continuous Waste Pyrolysis Machine from Beston Machinery

The good news is that you can find many easily customizable continuous waste tyre pyrolysis plant business plan templates online. These templates can help you to identify all of the factors that will impact the profitability and green credentials of your operations. Your business plan is important as it can help you to access the startup funds you need from either a bank, private investors or government green business grants. While you can find many free tire pyrolysis plant business plans online, it would be advisable to invest a small amount of money in a professional, detailed tire recycling plant business template.

Once you have found a business plan template to download, it’s time to start filling in all the details including the configuration of your plant, daily processing capacities, the location of your facility, the budget, etc. Creating a detailed tire recycling business plan will help you to make informed purchasing decisions when it comes to selecting the best rubber pyrolysis reactor suppliers. We recommend this brand for you – Beston.

The great thing about starting a continuous waste tyre pyrolysis plant in 2020 is that there are loads of tire to oil machine manufacturers and suppliers in the industry. This means that equipment prices are very competitive. There are now many affordable continuous tire pyrolysis plants, which are fully automated and equipped with tire shredders, meaning they only require a barebones workforce to run. The daily processing capacities of those plants can exceed 30 tons of tires, which equates to a lot of profitable fuel oil. Check this available resource for more info http://wastetoenergyindonesia.shop-worlds.com/.