Understanding Tyre Into Oil Pyrolysis Machine

Recycling technologies are becoming more popular by the day. This is mainly due to their ability to convert waste that humans produce to products that can be used. Additionally, the popularity of such technologies is also driven by the financial benefits that investors can accrue from recycling waste. The waste recycling industry is fast expanding, becoming more profitable with each turning day.

Among these attractive recycling, technologies are the tyre to oil machine. This machine is designed to turn some of the biggest human waste, the car tires into the products that can be used for other purposes. The machine is based on the commercial application of the tyre pyrolysis process.

Pyrolysis Technology

Pyrolysis is the process of thermal degradation of the tires in the absence of oxygen leading to the formation of pyro oil, pyro gas, carbon black (also known as char) and scrap steel.

The process in commercial organizations that recycling tires into oil takes place inside of the reactor, where the conditions are controlled to give rise of the perfect pyrolysis conditions. In the reactor, the air is deprived of oxygen while the pressure can be atmospheric or vacuum.

The Products Of The Pyrolysis Process

The main product of the tire to oil process is the pyro oil, with the most efficient machines yielding 60% -70% pyro oil. The oil is used in the heavy industry as a heating source. Refinement of the oil of also done to make the oil suitable for other uses such as home heating.

The gas that is produced is usually condensed. This turns the methane in the gas into a home heating source. As for the char, or carbon black, it is used to make coloring pigment. The scrap steel wires from the tires are collected and sold as scrap metal, also recycled to produce other steel products.

Pyrolysis Machines

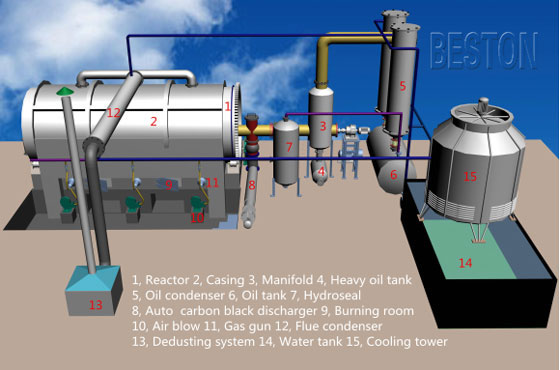

Although different plants may have different plant designs, there are basic parts that every plant should have. These parts are:

The Reactor

This is part of the system where the pyrolysis reaction takes place in.

The condensers

This is a system of plumbing that is designed to help the pyro gases condense. The size and length of the condenser do vary depending on the processing capacity of the plant.

The Oil Tanks

This is the vessel(s) that collect the resulting oil. For efficient collection, some plants have different oil tanks for oils different densities with one tank collecting the heaviest oil, while another collecting the middle-density oil and the other collecting the lightest oils.

The Cooling Plumbline

Finally every tyre into oil pyrolysis machine must have a plumb line and heat exchange tank to cool the oil that comes from the reactor. To get more info, please check this link: https://kingtigergroup.com/waste-tyre-to-oil-plant/.