Is The Cost Of Garbage Sorter Machine Worth The Money?

Are you looking to boost your recycling efforts? As you probably know, one of the most annoying things about recycling is the difficulty that comes with separating paper, plastic, glass, and other materials. Back in the day, this process needed to be done by hand. It takes a whole lot of time and effort to sift through all the garbage and separate what can be recycled from what must be sent to the landfill. Thankfully, automatic garbage segregator enables us to go through this process in a much more efficient manner. Keep reading to learn whether the cost of a garbage sorter machine can generate an excellent ROI.

Automatic Waste Segregation System

In the US, approximately half of the recycling facilities are now equipped with single-stream recycling machines. This has resulted in a tremendous increase in recyclables, as these machines serve over 100 million people. Although the system is far from perfect, it all works in a very simple manner that can prove to be the key to the widespread adoption of recycling. Experts say that people will never successfully increase recycling rates and less the process becomes more convenient. With advancements in technology, recycling facilities are starting to operate more efficiently.

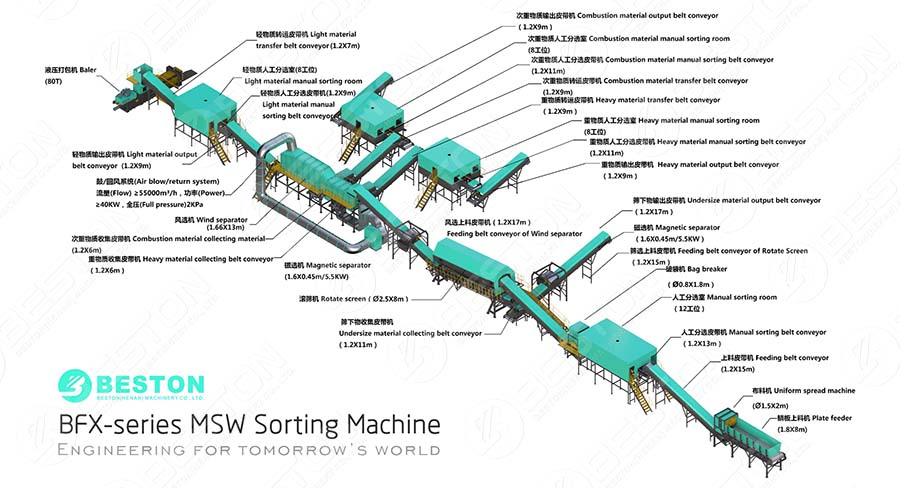

It’s worth noting that the most common waste recycling plant used is single-stream recycling. You can think of it as a very long conveyor belt on which mixed recyclables pass through several layers, each of which separates different materials for easier recycling. The first step involves a garbage truck delivering the materials to the garbage sorting machine. This is followed by a claw machine picking up the materials and placing them on top of the first conveyor belt. Below is a video for your reference.

The initial sorters are individuals who remove any item that might cause the waste sorting line to jump up. These items include hangers, plastic bags, and anything that is too big for the sorter. Next, the materials go through start screen is. These screens remove corrugated cardboard from the mix. Also, smaller items do not pass through the screen, and thus making them fall down to the next conveyor belt.

The waste materials will continue passing through more start screens, with the goal of separating arterioles of different sizes. When they pass through the medium start screens, paper is removed from the bunch. It’s interesting to learn that paper makes up more than 60% of all recycled materials in most recycling facilities. As for the recycled paper, you can have a paper tray machine to turn it into pulp molded trays.

Waste Sorting Line Design

Glass, plastic, and aluminum are the last to be sorted out. Additional sorters are used to remove them one by one. Once plastics are the only material left, infrared lasers are used to determine what kinds of plastic can be recycled. All the items left are sent to a landfill.

Now that you have an idea about the process of separating mixed recyclables, it’s easier to imagine how you can get an excellent return on your investment despite the high cost of garbage separation system. It’s high time that you contribute to the country’s recycling efforts to help conserve the environment. More about waste recycling projects can be found: https://bestonasia.com/.