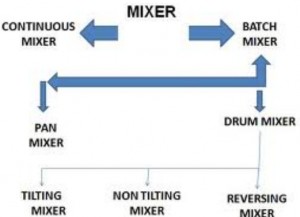

Simple Classification of Concrete Mixer

Concrete mixer is a machine that can mix sand, stones, aggregates and water etc. raw materials into concrete mixture. There are numerous types of concrete mixers in the market. We can classify them in the following methods.

Concrete mixer is a machine that can mix sand, stones, aggregates and water etc. raw materials into concrete mixture. There are numerous types of concrete mixers in the market. We can classify them in the following methods.

First, according to the power source of concrete mixers, they can be divided into diesel powered concrete mixer and electric powered concrete mixer. Diesel concrete mixer is especially suitable for those regions lacking of electricity.

Second, according to the movability of concrete mixers, we can classify them into fixed concrete mixers and portable concrete mixers. As the name suggests, fixed concrete mixer is fixed on a basis and its stationary, it has high efficiency and can be adopted in concrete batch plant, so it is widely applied to large size construction projects that need a long term to accomplish. On the contrary, portable concrete mixer is easy to move, they are widely used in small size construction site that need a short term to finish.

Third, according to the mixing principle of concrete mixers, they can be classified into self falling concrete mixer and forced concrete mixer. Self falling concrete mixer takes advantage of the raw materials’ weight during the mixing process. Self falling concrete mixers often are drum concrete mixers with small size, and they can be used to mix plastic concrete and semi-plastic concrete. Forced concrete mixer adopts forced mixing and its mixing effect is very strong, it has good mixing effect and high efficiency. Usually, it is adopted in a concrete batch plant. Forced concrete mixer is suitable for mixing hard dry concrete.

Forth, according to the operation mode of concrete mixers, they can be divided into continuous concrete mixer and circulating concrete mixer. Materials supply, mixing process and concrete discharge are conducted continuously in a long drum of continuous concrete mixer. The materials ratio and mixing time of continuous concrete mixer are hard to control and its mixing effect is not very good, so continuous concrete mixer is seldom used in modern construction. As for circulating concrete mixer, materials supply, mixing process and product discharge are separated with certain time interval. It has accurate weighing and good mixing effect. Therefore, most concrete mixers adopt circulating operation mode.

Forth, according to the operation mode of concrete mixers, they can be divided into continuous concrete mixer and circulating concrete mixer. Materials supply, mixing process and concrete discharge are conducted continuously in a long drum of continuous concrete mixer. The materials ratio and mixing time of continuous concrete mixer are hard to control and its mixing effect is not very good, so continuous concrete mixer is seldom used in modern construction. As for circulating concrete mixer, materials supply, mixing process and product discharge are separated with certain time interval. It has accurate weighing and good mixing effect. Therefore, most concrete mixers adopt circulating operation mode.

Fifth, according to the discharge mode of concrete mixers, they are divided into tilting type concrete mixer and non-tilting type concrete mixer.

If you also want to see the real products of all kinds of concrete mixers, go to http://concretemachinerypro.com/concrete-mixer/. The supplier is a trust manufacturer of concrete plants and mixers with over 30 years experience. Buying from them can’t be wrong.